CNT-1 is a compact and reliable microprocessor-based device designed for precise pulse counting in technological processes.

It is used in automation systems to monitor the number of products, cycles, machine revolutions, object passages through a control zone, and more.

Its flexible configuration allows the device to be used in manufacturing, transportation systems, packaging lines, machine tools, and other areas where reliable event counting is required.

⚙ Functional Capabilities:

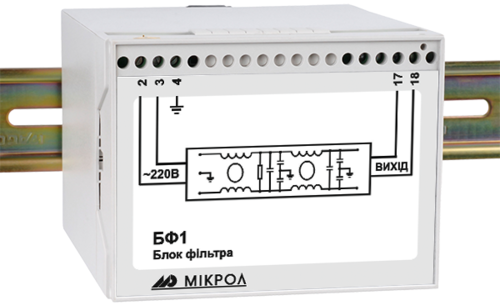

- 🧮 Pulse counting with noise and interference filtering

- 🎯 Setpoints (limits) – output signal generation when the preset value is reached

- 🔄 Input operating modes – start/stop, block, reset

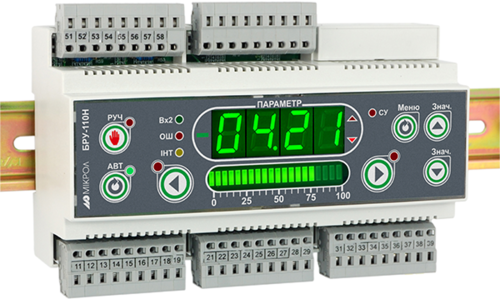

- ⚡ Equipment control via 2 digital outputs (switching mechanisms on/off, signaling)

- 🖥 Integration with industrial automation systems – via Modbus RTU or USB connection

- 💾 Data storage in non-volatile memory when power is off

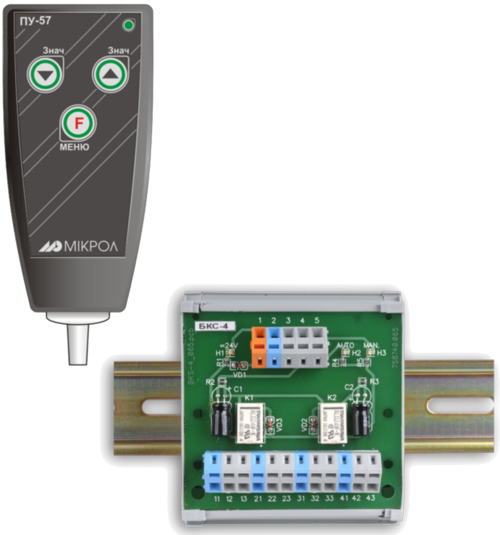

- ⚙ Parameter configuration via PC or optional button panel