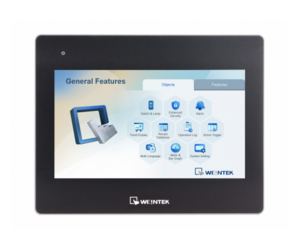

cMT-FHDX-820 is a high-performance visualization server designed for building modern automation systems.

It provides centralized processing, monitoring, and visualization of technological processes, allowing operators and engineers to access real-time data from anywhere.

👉 Additionally, the device can operate with CODESYS (optional), turning it into a fully functional PLC controller compliant with the IEC 61131-3 standard.

1️⃣ “Faceless HMI” Concept and Remote Control

- 📟 Models without a built-in display act as HMI servers that provide graphical visualization of technological processes.

- 📺 Mimic diagrams, trends, animations, and user interfaces are displayed on an external monitor via the HDMI port in Full HD (1920×1080) resolution.

- 📱 Operator interaction is possible through iOS / Android applications or PC software (cMT Viewer).

- 🔑 Supports Weincloud EasyAccess 2.0 (optional) — secure VPN access and remote monitoring.

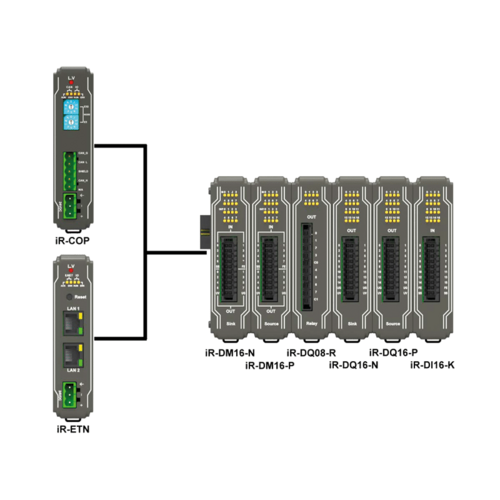

2️⃣ Broad Protocol and Connectivity Support

- 🔌 Over 300 drivers for PLCs, controllers, and measuring instruments.

- 🌐 Dual Ethernet ports for isolated remote connections and device polling.

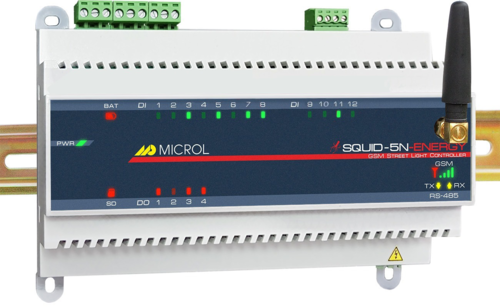

- 📡 RS-232 / RS-485 interfaces for legacy or specialized equipment.

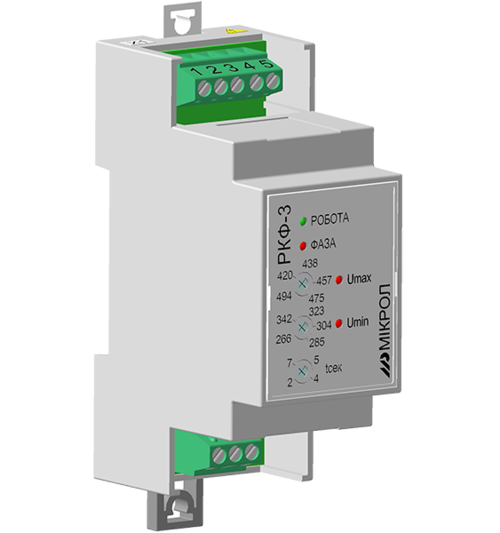

- 📤 Supported protocols: Modbus TCP/RTU, OPC UA, MQTT, FTP, HTTP/HTTPS, SQL, SNMP.

3️⃣ Powerful Data Processing Platform

- 💾 Data logging and archiving to microSD / USB.

- 🔄 Mathematical and logical data processing without modifying the PLC program.

- 📊 Supports Data Sampling, Event Logging, Recipes, and Scheduler functions.

4️⃣ Advanced Visualization and Interface

- 🎨 Project design in EasyBuilder Pro with support for animations, trends, mimic diagrams, and interactive elements.

- 📺 Visualization output to an external display via the HDMI port ensures convenient monitoring of process states without a built-in screen.

- 📱 In parallel, the operator can monitor or control the process via a mobile app or remote client.

- ✔️ CODESYS option 🧩 — enables operation as a PLC controller under the IEC 61131-3 standard.

5️⃣ Networking and IIoT Capabilities

- ☁️ MQTT Client / Server / Publisher — for integration with cloud services.

- 🖧 OPC UA Server — for communication with other platforms and SCADA systems.

- 📂 SQL Database — for data storage and historical records.

- 🌍 RESTful API — for integration with web systems and corporate dashboards.

6️⃣ Modularity and Scalability

- 👥 Multiple cMT Viewer clients can connect simultaneously for collaborative monitoring.

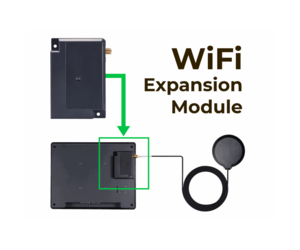

- 📶 Supports expansion modules (Wi-Fi, I/O).

- 🔍 Weintek cMT Series Overview:

- cMT-SVR — screenless HMI server;

- cMT-HDMI — HDMI output module;

- cMT-FHDX — Full HD controller for external visualization.